Non-Destructive Testing Jobs: A Guide to a Career in NDT

A career in NDT, or non-destructive testing, can be exciting, challenging, and very rewarding. Non-destructive testing jobs are available throughout Canada. NDT technicians are particularly in high demand in cities like Edmonton, Alberta.

There are many career paths, in a wide variety of industries, available in non-destructive testing. Those who are interested in the field can earn certifications for various testing methods at several different levels. With three levels of certification possible for each testing type, there are numerous opportunities for advancement within the NDT industry.

To become an NDT technician in Canada, candidates must complete extensive training, testing, and practical work experience. Technicians who are certified in various NDT methods at a high level will be hired for complex jobs and trusted by organizations to make important decisions about the safety and viability of their assets.

What a non-destructive testing technician does

Types of NDT technicians

NDT certification levels

Non-destructive testing jobs

Non-Destructive Testing Technicians

NDT technicians are trained to inspect and evaluate metals, materials, and other structures for flaws, defects, and damage. NDT inspection specialists use various tools and technology to conduct their testing and may be required to have additional specialized skills, such as mountain climbing training, in some cases. Therefore, non-destructive testing specialists require attention to detail and problem-solving skills, in addition to knowledge of mathematics and science. As well, they must have certain physical attributes including good vision and the ability to differentiate between colours, including shade and brightness.

Many different industries throughout Canada use NDT inspection services to ensure the safety and reliability of their assets. These include oil and gas, pipeline, mining, industrial construction, aircraft and rail transportation, heavy equipment manufacturing, and more. Therefore, NDT technicians can expect to work in many different sectors.

In Canada, a governing body, known as The Natural Resources Canada (NRCan) National Non-Destructive Testing Certification Body (NDTCB), is in charge of a program that certifies all NDT technicians. NRCan was appointed this role by the Canadian General Standards Board (CGSB).

For those wishing to become an NDT technician, the NRCan NDTCB requires certification from a Recognized Training Organizations (RTO). Various RTOs exist throughout the country, with different organizations approved in different provinces. The training organizations recognized in Alberta include:

- Canadian Institute for Non-destructive Evaluation

- IDL Inspection Ltd.

- Keyano College

- Metalogic Inspection Services Inc.

- Northern Alberta Institute of Technology

- Quality Control Council of Canada

- Southern Alberta Institute of Technology

Types of NDT Technicians

Non-destructive testing is conducted using various methods. Each NDT method requires separate training and certification. Therefore, many different types of NDT technicians exist. A single technician may have more than one certification. That is to say, they can conduct non-destructive testing jobs using various methods. In addition, technicians can be certified at various levels (Level 1, Level 2, and Level 3). Higher levels indicate more advanced skills and additional responsibilities.

CEDO

In many cases, technicians will begin their career in NDT as a CEDO, conducting radiation testing. A CEDO, or Certified Exposure Device Operator, is certified to work with radiation. In Canada, all CEDOs must be certified by the Canadian Nuclear Safety Commission (CNSC) and only a CEDO can legally perform gamma radiography and operate an exposure device. To become a CEDO, a 40-hour CEDO (Certified Exposure Device Operator) course is required in addition to work experience and testing. A CEDO must have basic math skills and must be able to use computational operations.

The job of a CEDO is to operate industrial gamma radiography exposure devices, in order to test various assets. CEDOs must be able to safely handle and operate these devices, as well as radiation detection and monitoring equipment.

Ultrasonic Technician

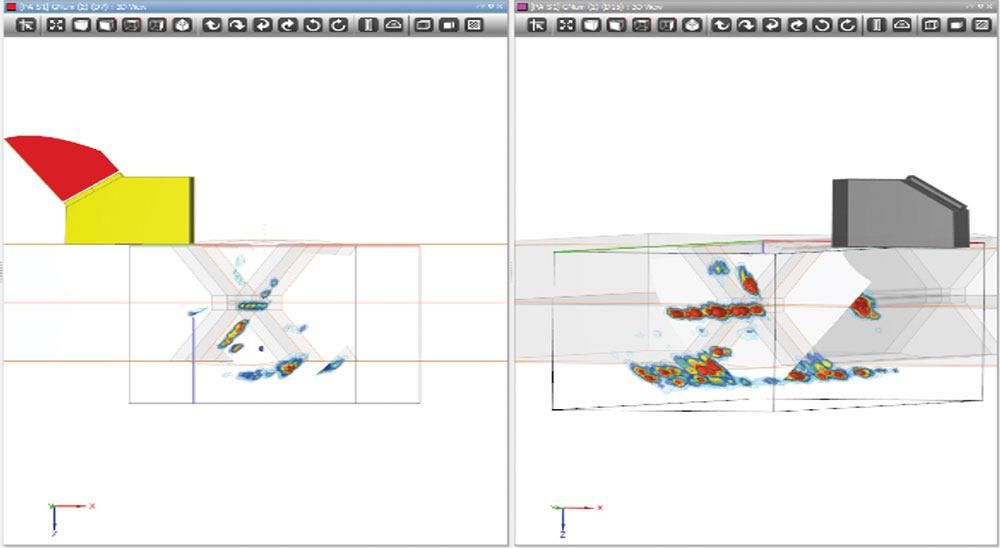

Ultrasonic technicians, or UT technicians, are trained to use the ultrasonic testing method. UT technicians use ultrasonic transducers to send high-frequency sound waves into a material to detect flaws and defects inside. Subsequently, the UT technician evaluates the provided graph to determine the possible depth, size, nature and orientation of a flaw or defect. This NDT method can also determine the thickness of the material.

Radiography Technician

A radiography technician, or RT technician, employs technology using x-rays or gamma rays to evaluate the internal soundness of a material. The technician must be able to interpret the resulting output of the test to determine if any flaws or defects are present in the material.

Additional Types of NDT Technicians

There are many other types of NDT technicians – one for every NDT method.

Other NDT technician types include:

- ET (Eddy-current or Electromagnetic Testing) technicians

- MP (Magnetic Particle Testing) technicians

- VT (Visual Testing) technicians

- PT (Liquid Penetrant Testing) technicians

In order to become a technician for a particular NDT method, applicants must complete training at an RTO. After that, NDT trainees must complete practical work experience with an NDT company. Following this work experience, the NDT trainee must pass the NRCan practical exam.

Levels of Certification

For each type of NDT certification, there are three levels of qualification. Each level allows the technician to offer more advanced services. To achieve a particular level of certification, technicians must obtain industry-specific work experience, as well as complete written and practical examinations.

Level 1 ET, RT and UT technicians must complete a minimum of three months of experience. Level 2 certification requires nine months of work experience and for Level 3 eighteen months is necessary. For MT, PT and VT technicians, Level 1 certification requires a minimum of one month of work experience and Level 2 certification requires three months. Finally, to achieve Level 3 certification a technician must complete twelve months of work experience.

The higher the level of certification, the more responsibility and the more complex evaluations a technician can complete. In fact, the supplementary knowledge that is necessary for a Level 3 certification requires additional experience above and beyond that of any single testing method. A combination of education, training and experience provides this knowledge. For a technician to be awarded Level 3 certification, a record of this additional experience must be presented to the certification body in the form of a CV (curriculum vitae).

Technicians at different levels will have different capabilities and responsibilities and will be able to perform different non-destructive testing jobs. These include:

Level 1

- Perform specific calibrations

- Implement a specific NDT method (only on certain components)

- Conduct evaluations to determine if the component is acceptable or should be rejected

- Level 1 technicians require supervision by a higher level tester

Level 2

- Posses the same capabilities as Level 1 technicians

- Set up and calibrate equipment

- Conduct NDT testing and evaluation in accordance with applicable codes, standards, and specifications

- Interpret and document the results of the inspection

- Act as a supervisor for lower level technicians

- Provide on the job training for Level 1 technicians

Level 3

- Posses the same abilities as Level 2 technicians

- Establish techniques and procedures

- Interpret codes, standards, and specifications

- Determine which NDT methods and techniques to use

- Possess knowledge of materials, fabrication and product technology

- Train and test Level 1 and Level 2 technicians

- May be in management positions or become consultants

Non-Destructive Testing Jobs – Employment in the NDT Industry

The more NDT methods you are certified to conduct, and the higher the level of certification you have, the more non-destructive testing jobs you’ll be qualified for. As well, a higher level of certification results in higher pay. The opinions and decisions of high-level technicians are also viewed as more reliable than technicians with lower-level certifications.

NDT technicians often make judgements that can have significant safety and financial consequences. Therefore, they must be confident in their work and the results they are providing. Technicians can confidently perform more complex jobs and evaluations when they have a higher level of certification.

Looking for NDT jobs in Canada? Buffalo Inspection Services is Western Canada’s largest and most wide-reaching non-union provider of non-destructive testing services. Buffalo is looking for experienced technicians to join their family of professionals.

Find a career in NDT that is a fit for you! Check out Buffalo’s job listings – NDT Jobs