Magnetic Particle Inspection and Fatigue: The Impact on Probability of Detection

Not even the most advanced non-destructive testing (NDT) methods, including Magnetic Particle Inspection (MPI), are foolproof. Regardless of which NDT technique is used to evaluate a material, not all defects will be found. That being said, experienced NDT technicians can get extremely accurate results when they are aware of conditions that may impact the detection of flaws. For instance, a significant factor that can impact the probability of detection (POD) when using Magnetic Particle Inspection, or MPI testing, is fatigue.

Let’s take a look at Magnetic Particle Inspection and how fatigue impacts MPI testing.

What is Magnetic Particle Inspection?

How does fatigue impact the POD for Magnetic Particle Inspection?

How to increase the probability of detection with MPI testing

What is Magnetic Particle Inspection?

Magnetic Particle Inspection is a type of non-destructive testing. It is used to detect flaws on the surface or near the surface of ferromagnetic materials, such as iron and steel.

MPI testing is especially useful for detecting minor imperfections. This includes pores, cracks and other discontinuities. As a result, this NDT method is often used in welding inspections.

The benefits of Magnetic Particle Inspection include quick testing and immediate results. As well, this NDT method has the ability to detect flaws in materials with irregular shapes. Above all, MPI testing provides great defect resolution.

MPI testing can be conducted using several different techniques. One of the most common types of Magnetic Particle Inspection is the Yoke technique. This technique uses a portable hand-held device with an AC/DC or permanent Yoke to magnetize a material. The Yoke technique is versatile and relatively inexpensive to employ.

How is the MPI test carried out?

Magnetic Particle Inspection is conducted using several steps:

- Clean the surface of the material.

- Create a magnetic field in the material.

- Apply magnetic particles to the surface of the material.

- Remove any excess magnetic particles to uncover indications (shown by particle groupings).

- Clean and demagnetize the part, if necessary.

Detecting indications is straightforward in some cases. However, the probability of detection using MPI testing can become more difficult if a material has experienced fatigue.

How does fatigue impact the POD for Magnetic Particle Inspection?

Work hardening and fatigue are caused by physical processes and deformations imposed on a metal. For example:

- Plastic deformation

- Welding activities

- Repeated stress and strain on the material

As mild steel experiences work hardening and fatigue, the magnetic properties of the steel change. Let’s take a look at the kinds of changes you can expect.

Property Changes Due to Fatigue

When metal becomes fatigued, three significant properties change.

- Coercivity Increases – the metal becomes more resistant to changes in magnetization.

- Remanence Decreases – after the magnetizing force is removed, very little magnetism remains.

- Permeability (μ) Decreases – fatigued metal becomes more difficult to magnetize.

When discussing Permeability, it’s important to note that Permeability (µ) is a ratio – a function of B and H. That is, B = µH, where B = flux density in Gauss and H = magnetizing force in Oersteds. So, when μ decreases, the amount of magnetizing force remains the same and the codes still mandate a 30 Oersted value for B. H for AC yokes is fixed. As a result, there is only physical spacing to reduce magnetizing force.

This being said, it is important to be cognizant of the variables in order to get a result and maintain probability of Detection. B is generally overstated in the codes to a value that is three times that necessary. This results in spurious indications and a low probability of detection for Yoke MPI (i.e. around 44%).

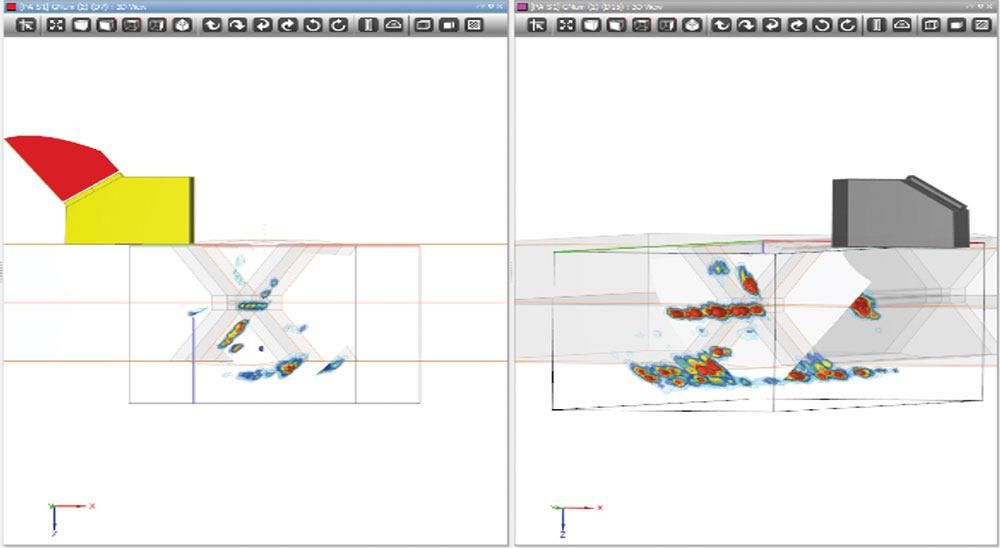

To further illustrate the extent to which fatigue affects permeability, we’ve provided a visual representation below. What you’ll notice in this diagram is that the permeability of a cracked or fatigued material is approximately 30% less than the material in its original state.

When it comes to Magnetic Particle Inspection, changes in permeability have the most significant impact on POD.

But how does permeability impact the probability of detection when using MPI testing? Let’s take a look.

Impacts of Decreased Permeability on Magnetic Particle Inspection

Decreased permeability results in a lower probability of detection when using Magnetic Particle Inspection. More specifically, POD decreases because MPI testing using a permanent magnet (like that used with the permanent Yoke technique) does not allow the NDT technician to control magnetic current. As a result, the inspector may reach saturation levels, even though the material is not magnetic enough to accurately detect flaws. Overall, decreased permeability makes it difficult to effectively uncover indications, especially those that are not large or surface breaking.

The graph below demonstrates the relationship between permeability and induced magnetism based on the strength of the external magnetic field that is applied.

The probability of detecting indications with MPI testing is especially low when evaluating fatigued materials using the AC/DC or permanent Yoke technique. This is because the technique does not allow the NDT technician to control the amount of magnetization. Rather, the AC/DC or permanent Yoke technique is a one-size-fits-all method of testing.

In addition, welded and fatigued materials exhibit variances in permeability. In other words, different areas of the material (e.g. parent material, heat-affected zone, weld) will have different permeability values. Again, because it is a one-size-fits-all method, the AC/DC or permanent Yoke technique does not lend well to testing materials with varying permeability. However, there are ways to improve the probability of detection when using MPI testing.

How to increase the probability of detection with MPI Testing

While the POD for Yoke MPI testing is low, other Magnetic Particle Inspection techniques offer a higher probability of detection. In particular, MPI testing techniques that allow for control over the magnetizing force (i.e. current control) have the best probability of detection.

MPI Techniques

Several common techniques are used to induce magnetization when employing Magnetic Particle Inspection. These include:

- Prods magnetization

- Longitudinal magnetization

- Circular magnetization

- Yoke magnetization

- Multi-vector magnetization

Of these MPI testing techniques, the ones that allow for the most control over magnetic current will have the highest probability of detection for fatigued materials.

In addition to employing a more reliable technique when fatigue is present, NDT technicians who are aware of the impacts of fatigue and changes in permeability can use this knowledge to offer better results in the field. Leading NDT companies, like Buffalo Inspections, employ knowledgeable technicians who are familiar with the implications of magnetic physics and can ensure the best probability of detection.

Get the Most Reliable NDT Results with Buffalo Inspections

The experienced NDT technicians at Buffalo Inspections provide the most detailed and reliable testing possible. Our highly trained technicians have extensive experience in the field and provide accurate testing using state-of-the-art NDT inspection technology.

For more information on Magnetic Particle Inspection and other advanced non-destructive testing methods, contact Buffalo today.